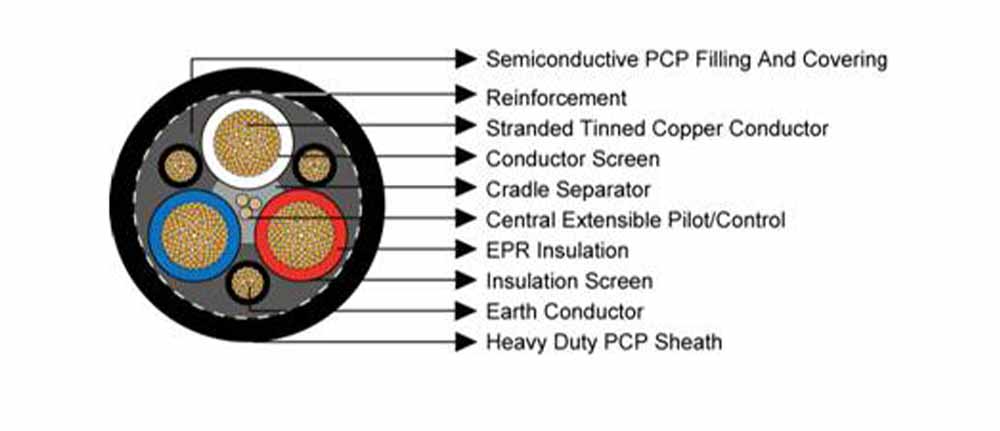

Type 245 Mining Cable Construction

| VOLTAGE | 1.1kV (Type 245.1) 3.3kV (Type 245.3) 6.6kV (Type 245.6) |

| CONDUCTOR | Tinned Copper |

| CONDUCTOR SCREEN | Paper Separator (1.1kV) Semi-conducting thermosetting material (3.3kV and above) |

| INSULATION | EPR (Ethylene Propylene Rubber) |

| INSULATION SCREEN | Synthetic tape (1.1kV) Semi-conducting thermosetting material (3.3kV and above) |

| SCREEN | Semi-conductive PCP (Polychloroprene) |

| EARTH COVERING | Semi-conductive PCP (Polychloroprene) |

| ASSEMBLY | Three screened power cores with earth and pilot core with cradle separator |

| INNER SHEATH | - |

| REINFORCEMENT BRAID | Polyamide yarns in open weave |

| OUTER SHEATH | HD-PCP (Heavy Duty Polychloroprene) |

Type 245 Mining Cable Application

Type 245 cables are mainly used as longwall shearer cables, and also for continuous miners and peripheral longwall cables. The cable has 3 central pilots for earth continuity monitoring and for control circuits.

Type 245 Mining Cable Characteristics

Voltage Rating

- 1.1kV – Type 245.1

- 3.3kV – Type 245.3

- 6.6kV – Type 245.6

Type 241 Mining Cable Standards

- AS/NZS 1802:2003

- AS/NZS 1125

- AS/NZS 3808

- AS/NZS 5000.1

Type 245 Mining Cable Advantages

- High Flexibility: These cables are highly flexible, allowing for easy installation and movement in confined mining spaces.

- Robust Construction: The flexible rubber sheathing ensures the cable can withstand physical stress and environmental factors.

- Safety Compliance: Adhering to AS/NZS standards, these cables ensure maximum safety for mining operations.

- Enhanced Control: The inclusion of control circuits allows for better management and operation of mining machinery.

- Environmentally Friendly Mining Cables: Designed to minimize environmental impact, these cables are part of a sustainable mining solution.

- Type 245.1 Mining Cable

- Type 245.3 Mining Cable

- Type 245.6 Mining Cable

| NO. OF CORES | NOMINAL CONDUCTOR AREA mm2 | TRAND SIZE No/mm | NOMINAL INSULATION THICKNESS mm | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/100m |

||

|---|---|---|---|---|---|---|---|---|---|---|

| STRAND SIZE No/mm | AREA OF SCREEN mm2 | STRAND SIZE No/mm | THICKNESS OF COVERING mm |

|||||||

| 3 | 16 | 133/0.40 | 2.0 | 69/0.25 | 1.8 | 28/0.25 | 0.8 | 4.1 | 42.6 | 235 |

| 3 | 25 | 259/0.36 | 1.6 | 91/0.25 | 1.8 | 28/0.25 | 0.8 | 4.2 | 43.4 | 269 |

| 3 | 35 | 287/0.40 | 1.6 | 140/0.25 | 1.4 | 28/0.25 | 0.8 | 4.4 | 45.6 | 315 |

| 3 | 50 | 703/0.30 | 1.7 | 120/0.30 | 1.0 | 28/0.25 | 0.8 | 4.8 | 48.4 | 390 |

| 3 | 70 | 988/0.30 | 1.8 | 180/0.30 | 1.0 | 28/0.25 | 0.8 | 5.1 | 53.9 | 501 |

| 3 | 95 | 1332/0.30 | 2.0 | 150/0.30 | 1.0 | 28/0.25 | 0.8 | 5.6 | 60.4 | 630 |

| 3 | 120 | 1702/0.30 | 2.1 | 195/0.30 | 1.2 | 28/0.25 | 0.8 | 6.0 | 65.5 | 765 |

| 3 | 150 | 2146/0.30 | 2.3 | 235/03.0 | 1.2 | 28/0.25 | 0.8 | 6.3 | 70.5 | 915 |

| NO. OF CORES | NOMINAL CONDUCTOR AREA mm2 | TRAND SIZE No/mm | NOMINAL INSULATION THICKNESS mm | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/100m |

||

|---|---|---|---|---|---|---|---|---|---|---|

| STRAND SIZE No/mm | AREA OF SCREEN mm2 | STRAND SIZE No/mm | THICKNESS OF COVERING mm |

|||||||

| 3 | 25 | 259/0.36 | 3.0 | 91/0.25 | 1.5 | 28/0.25 | 0.8 | 5.2 | 51.1 | 338 |

| 3 | 35 | 287/0.40 | 3.0 | 140/0.25 | 1.0 | 28/0.25 | 0.8 | 5.4 | 54.5 | 398 |

| 3 | 50 | 703/0.30 | 3.0 | 120/0.30 | 1.0 | 28/0.25 | 0.8 | 5.7 | 56.8 | 490 |

| 3 | 70 | 988/0.30 | 3.0 | 180/0.30 | 1.2 | 28/0.25 | 0.8 | 6.0 | 61.2 | 592 |

| 3 | 95 | 1332/0.30 | 3.0 | 235/0.30 | 1.2 | 28/0.25 | 0.8 | 6.4 | 66.6 | 739 |

| 3 | 120 | 1702/0.30 | 3.0 | 300/0.30 | 1.2 | 28/0.25 | 0.8 | 6.7 | 71.0 | 870 |

| 3 | 150 | 2146/0.30 | 3.0 | 375/0.30 | 1.2 | 28/0.25 | 0.8 | 7.0 | 75.2 | 1028 |

| NO. OF CORES | NOMINAL CONDUCTOR AREA mm2 | TRAND SIZE No/mm | NOMINAL INSULATION THICKNESS mm | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH mm | NOMINAL OVERALL DIAMETER mm | NOMINAL WEIGHT kg/100m |

||

|---|---|---|---|---|---|---|---|---|---|---|

| STRAND SIZE No/mm | AREA OF SCREEN mm2 | STRAND SIZE No/mm | THICKNESS OF COVERING mm |

|||||||

| 3 | 50 | 703/0.30 | 5.0 | 120/0.30 | 1.4 | 28/0.25 | 0.8 | 6.7 | 67.2 | 635 |

| 3 | 70 | 988/0.30 | 5.0 | 180/0.30 | 1.4 | 28/0.25 | 0.8 | 7.0 | 71.7 | 755 |

| 3 | 95 | 1332/0.30 | 5.0 | 235/0.30 | 1.4 | 28/0.25 | 0.8 | 7.4 | 77.1 | 905 |

| 3 | 120 | 1702/0.30 | 5.0 | 300/0.30 | 1.4 | 28/0.25 | 0.8 | 7.7 | 81.3 | 1050 |

| 3 | 150 | 2146/0.30 | 5.0 | 375/0.30 | 1.4 | 28/0.25 | 0.8 | 8.0 | 85.8 | 1210 |

Why Huadong Cable

Our vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Main Products

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees